Disposable plugs, earmuffs, moulded ear plugs... many options exist to protect the hearing of employees exposed to noise. However, when it comes to ensuring the comfort of a hearing protector, not all solutions measure up. The reason for this is often found in the manufacturing methods used. How are Cotral Lab moulded ear plugs made? Let's study their manufacturing process, step by step.

SUMMARY

- Taking an impression (mould) of the ear

- 3D modelling

- Production

- Logistics

- Delivery

- Behind the technology: a team passionate about your hearing safety

Taking an impression (mould) of the ear

Fabrication of moulded ear plugs starts with taking an impression of the ear. When one of our Cotral Lab representatives visits a company to equip the employees with custom moulded hearing protection and advise them about the risks of noise, he or she undertakes the following in accordance with a strict protocol:

- Discussion with the future wearer: to understand his or her hearing history and to ascertain if there are contra-indications to taking the impression (excessive wax, recent operation, ear infections, etc.)

- Choosing the most suitable level of protection: by using the SAPAN Method and reviewing the noise environment with the safety manager and the wearer, the Cotral representative chooses the most appropriate model and filter as determined by the level of noise exposure, the need for communication, and the use of other protective equipment.

- Otoscopy (examination of the ear canal with a special instrument): to check if there is a wax plug or irritation that would make it impossible to take an impression.

- Insertion of a foam and the moulding paste: the Cotral representative will insert a protective foam plug and then inject the silicone moulding paste into the ear canal.

- Drying: three to five minutes are needed for the paste to dry. During this step it is important not to speak because any movement of the jaw could alter the shape of the mould.

- Removal and checking of the mould: once the paste has hardened, the Cotral representative removes it from the wearer's ear and performs a quality control check.

- Sending the moulds to Cotral Lab’s HQ: after checking the quality of the moulds, they are scanned by a 3D scanner and the digital files are sent electronically to Cotral Lab head office in Normandy, France.

3D modelling

Our 3D modellers receive the three-dimensional scans of the impressions and begin to digitally rework them. Modelling is a precise and essential stage in the process because it is here that the parameters that give the best performance and optimal comfort are applied:

- The digital impressions are cut and adjusted to take the form of the future hearing protection while retaining the portion intended to enter the ear canal.

- The filter insert is positioned.

- A unique ID code is added.

Following modelling, the enhanced designs of the protective devices are sent to production to be 3D printed.

Production

25 years of experience in the field have allowed Cotral Lab to develop the optimal fabrication techniques. In the past, Cotral Lab manufactured its hearing protections by hand using silicone, which is still the method used for many other products currently on the market.

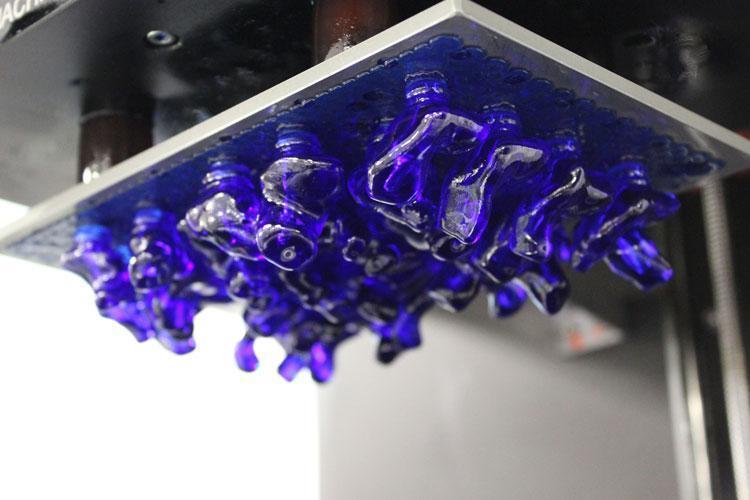

In 2010 Cotral Lab moved to 3D printing for better precision and to improve the effectiveness of our hearing protectors.

3D printing is a method of manufacturing an item by adding material in successive layers. It brings the following benefits:

- With 3D printing, methods of manufacture can be duplicated precisely.

- Because of this duplication, successive productions of a protective device are identical, unlike in manual manufacture.

- Most importantly, 3D printing achieves higher efficiency rates than hand-made hearing protection devices.

The method used at Cotral Lab is very similar to that used in dental prosthetics, resulting in high precision, superior quality (without material residues) and conformity with hygiene standards.

Cotral Lab is constantly innovating its fabrication processes and can now guarantee 96% effectiveness of its hearing protectors. For comparison, the measured effectiveness is 31% for foam ear plugs and 75% for plugs made from silicone.

Since 2010, our moulded ear plugs have been manufactured as follows:

The information needed to manufacture the protective device is transmitted from the modelling area to the production area. The protective devices are not made individually but in groups of similar products (model, colour, etc.). The capabilities of 3D manufacturing are such that each hearing protector can be manufactured according to its own parameters.

Layer by layer, micron by micron, it takes between one and two hours for this first stage in the manufacturing process to be completed.

Following this step, the devices are removed from the 3D printer, and are inspected, cleaned and dried before moving to the finishing stage. This step is essential because it allows the protective device to obtain its sheen, its resistance and its bio-compatibility. All these features make it possible to ensure precision of less than 100 microns (thickness of a human hair).

Once these finishing stages are complete, the different accessories are added and, following yet another quality check, the moulded plugs are sent for dispatch.

Logistics

At this stage, Cotral Lab's experts can rely on the help of a robot which assists in numerous tasks:

- A digital code indicates which filter is to be inserted into each protective device.

- The left and right ear plugs are then paired together, checked yet again and are transferred to an area where they are boxed, ready for dispatch.

This robot, which is identical to those used in pharmaceutical industries, guarantees the traceability of your custom made protective devices.

Delivery

Approximately 3 to 4 weeks are necessary to complete production. Then the packages are shipped to our Australian offices, where they are made ready for distribution to our local customers.

Behind the technology: a team passionate about your hearing safety

New technologies play a major role in the production of Cotral Lab moulded plugs. However, these technological advances would mean nothing without the know-how of all those involved in the production of our custom made protective devices.